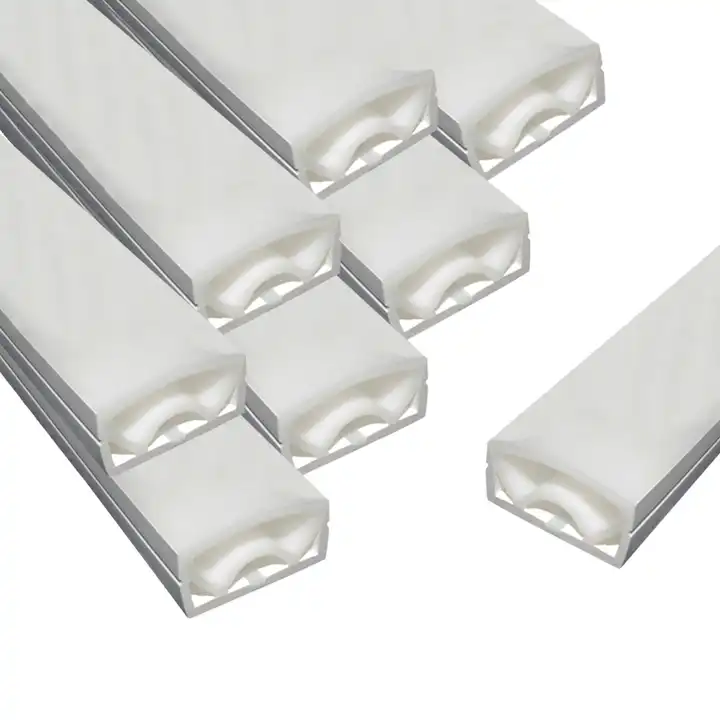

When it comes to ensuring comfort and energy efficiency in our homes and workplaces, one often overlooked but crucial component is the door bottom seal strip or stopper. A high-quality door bottom seal strip plays a significant role in maintaining indoor climate control, preventing drafts, and enhancing the overall aesthetic appeal of your doors. In this article, we will explore the benefits of using high-quality door bottom seal strips and why they are a worthy investment for any property owner.

Home

Home

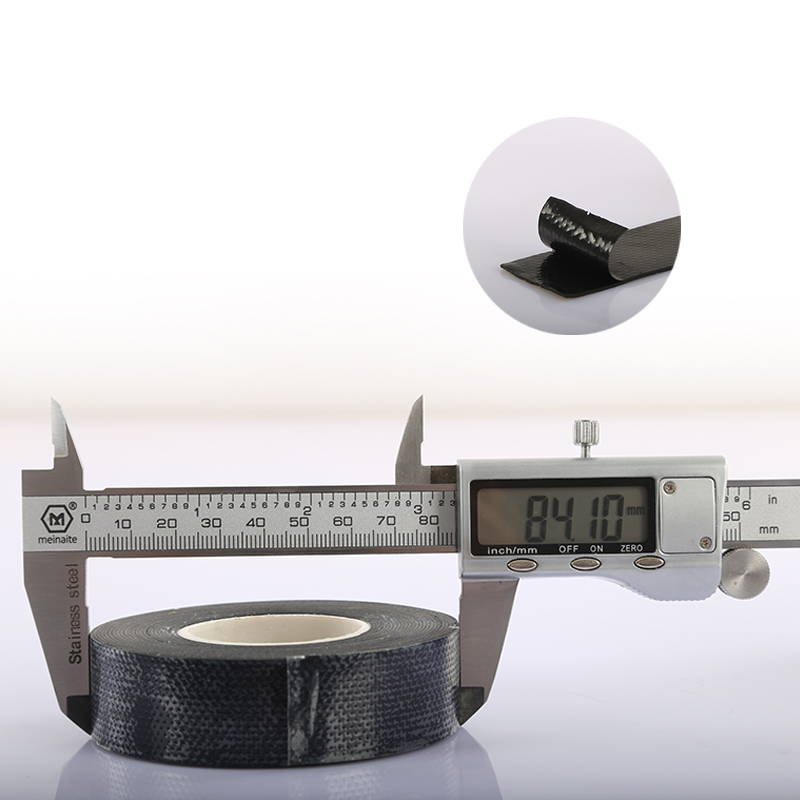

Whether sealing a leaky pipe or temporarily fixing a broken tool, black PVC tape can provide a quick and reliable solution until a more permanent fix can be made Whether sealing a leaky pipe or temporarily fixing a broken tool, black PVC tape can provide a quick and reliable solution until a more permanent fix can be made

Whether sealing a leaky pipe or temporarily fixing a broken tool, black PVC tape can provide a quick and reliable solution until a more permanent fix can be made Whether sealing a leaky pipe or temporarily fixing a broken tool, black PVC tape can provide a quick and reliable solution until a more permanent fix can be made